What if your business could establish a culture that harnesses quality as an operational weapon? What if you could make quality a repeatable, instinctive pattern of work that puts your company at the front of the pack?

The past couple of years haven’t been easy for businesses. The snail-paced unfolding of Brexit brought uncertainty and disruption for British and EU businesses, and anyone connected to them.

Then the ravages of COVID-19 shut large swathes of the world economy down and brought the Great Resignation in its wake. And now, inflation is rocketing skyward, the ‘r’ word is on everyone’s lips, and the cheap debt of the last decade is set to be curtailed by the Federal Reserve’s hiking of interest rates.

It’s clear that we’re in the middle of a rough patch. Businesses need to take measured, proactive steps now to weather the storm and make themselves as strong, healthy, and competitive as they can be.

In times like these, it can be tempting to reach for the nuclear option and take dramatic evasive action: diversification, cost-cutting, remodeling, and risk analysis are the order of the day.

Culture doesn’t get much of a look-in. But here’s why that’s a mistake – and why focusing on quality, and how to graft it into the heart of your cultural DNA, is one of the best things your business can do to prepare for the next few years.

- What is a culture of quality?

- Why does a quality culture matter?

- The four corners of a quality culture

- The role of leadership in a culture of quality

- Choosing the right tools for a quality culture

- Conclusion: Make a quality culture your objective

What is a culture of quality?

Quality management used to be a tickbox exercise looked after by a single department: document procedures, audit processes, measure product output, get a certificate for the wall, rinse, and repeat.

Forward-thinking business leaders are realizing there’s a better way.

Adhering to international quality standards like ISO 9001 has always been important for highly regulated industries like food and life science. But the increasingly competitive and thorny macroeconomic environment means the emphasis is now shifting for all businesses. Quality is evolving from ‘bare minimum must-have’ to a business-wide enabler of growth, continuous improvement, and competition-busting.

And to that end, more and more companies are attempting to instill quality into the heart of their operational cultures.

Simply put, a culture of quality is one where all employees seamlessly integrate quality into their daily activities. Rather than a discrete quality management system checking and enforcing actions from afar, quality becomes automatically repeated and ‘lived’ by all colleagues.

The core ingredients of this day-to-day quality emphasis include:

- Customer centricity, with constant evaluation of their needs and responsive actions as a result;

- Consistent, collaborative evaluation of process effectiveness, with intentional communication of improvement opportunities;

- Constant awareness of how product and service quality connects to the individual day-to-day.

Savvy leaders are realizing that ‘culture’ – ‘the way we do things around here’ – will always prevail over artificial attempts to condition behavior with policies and procedures. Only by loading quality into the business culture can long-term competitive advantage be achieved.

Why does a quality culture matter?

Besides the obvious – bringing safe, compliant products to market and keeping them there for your customers to buy – a quality culture can have dramatic transformative effects for your business and your bottom line.

While Harvard Business Review found that companies with mature quality cultures spend around $350m less every year fixing mistakes than companies without them, a real quality culture:

- Maximizes customer satisfaction;

- Reduces churn;

- Opens your total accessible market;

- Encourages growth;

- Saves money with a right-first-time approach: the ‘1-10-100’ quality rule holds that $1 spent on preventing defects equals around $10 spent on quality review, and about $100 spent on fixing existing defects.

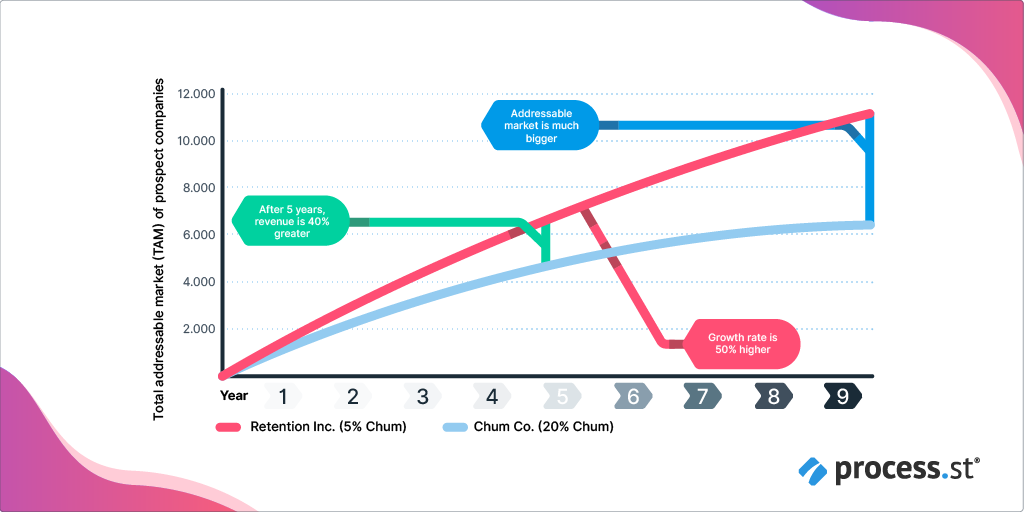

Marginal improvements, like a reduction in churn from higher-quality processes, can be transformational in the long run, as this graph shows:

Above all, a recent Qualio consumer survey found that the American public, specifically in a life science context, are acutely conscious of the quality and integrity of the products they access. 84% of consumers would factor an FDA ‘score’ of a company’s quality culture into their decision-making process, and 73% actively follow news and updates about healthcare products.

The intense and often vitriolic clash of ‘vaxxers’ versus ‘anti-vaxxers’ in the wake of COVID-19 throws this into sharp relief: people care, strongly, about the safety and quality of the business processes lurking behind the products they use every day.

Quality matters, and increasingly so. Your business culture needs to reflect that fact from top to bottom.

The four corners of a quality culture

Do you want to build a quality culture for your organization? Start with these four steps.

1. Planning

Who are your customers, and potential customers? What are their needs, and the needs of your broader stakeholders? How will you meet those needs, and adapt to future potential needs?

Answering these questions is crucial for the foundation of your quality culture; the needs of your stakeholders will govern how every layer of your business operates each day.

Take a close, objective look at any internal issues which might hamper your ability to meet these needs. Things to consider include:

- Relationship with your staff and stakeholders, including partners and suppliers;

- Resources and knowledge (capital, people, processes, and technologies);

- Risk appetite;

- Assets;

- The product/service(s) you offer;

- Current standards, guidelines, models, and ways of working;

- Information systems;

Then explore the external issues which might have a bearing on your business culture and impact the products and services you provide. Conduct a PESTLE analysis to pinpoint the political, economic, social, technological, legal, and environmental factors at play for your business.

Then bring those internal and external issues together into a SWOT analysis of the strengths, weaknesses, opportunities, and threats you’ll need to address, harness, or suppress.

2. Assurance

As we’ve seen already, the ultimate objective of a quality culture is to make the meeting of customer needs the automatic, repeatable core of your entire company’s daily activities.

Designing easy-to-follow processes which make this happen isn’t easy. And the process needs to be collaborative: there’s no use designing complex, beautifully engineered business processes which look perfect on paper but which aren’t followed day to day.

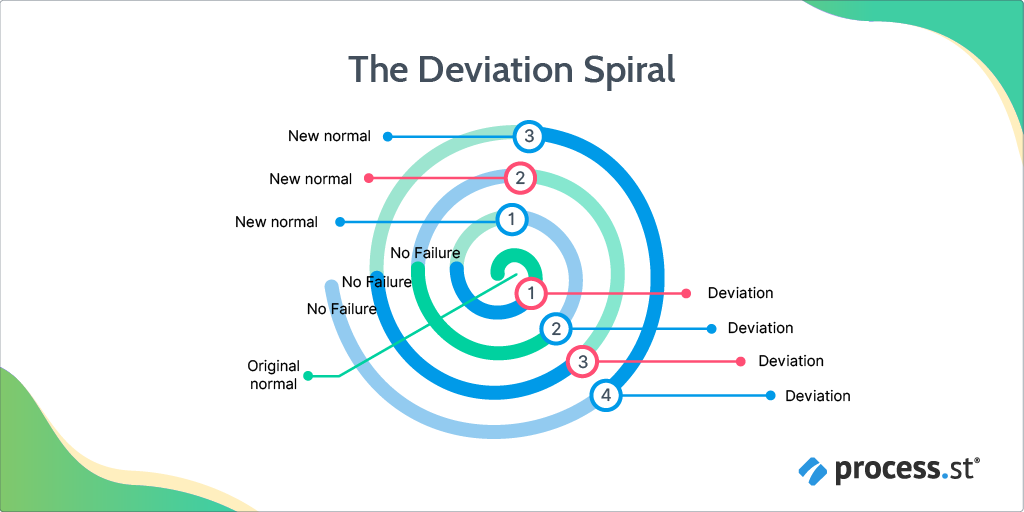

In this context, you should beware of the ‘deviation spiral’. Your team will naturally look for the fastest, easiest way to complete things, and will ‘deviate’ from documented processes to meet this aim. Small deviations will be cautiously experimented with, and will then crystallize into ‘the way we do things’ before new deviations take place.

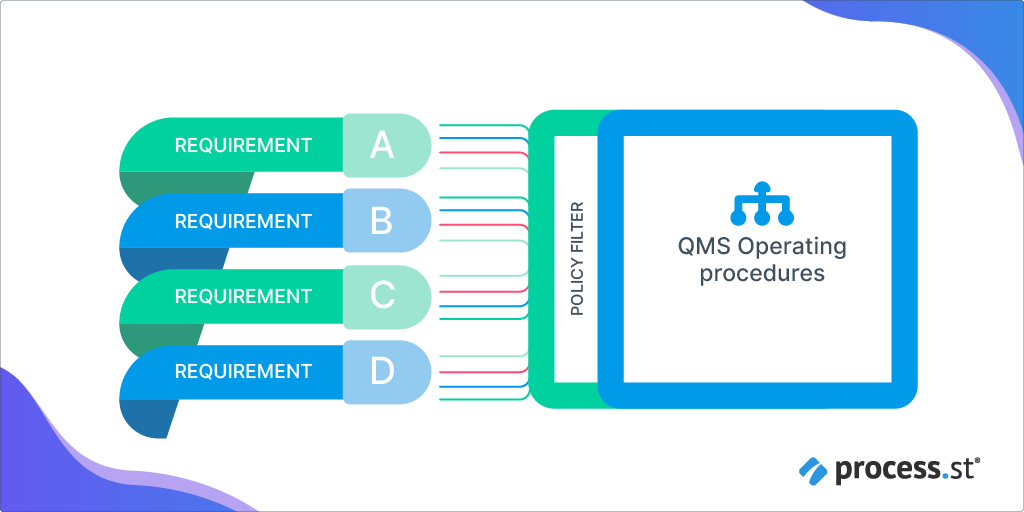

Your quality culture needs to work with, not against, the people on the frontline of your business processes. Start with your stakeholder requirements and work your way through to the desired inputs and outputs which will structure your processes, making sure you gather feedback and suggestions as you go.

Remember: the more your colleagues feel a sense of ownership of, and connection to, your ways of working, the more confident they’ll feel to suggest continuous improvement opportunities and the less chance of a deviation spiral unwinding behind your back.

Proper assurance that your operational goals can be achieved with minimal variation and error is a crucial component of any quality culture.

3. Control

Closely connected to assurance is control. The best quality cultures are the most introspective, giving all employees the chance to frequently reflect on their work and consider whether quality requirements are being fulfilled.

Reviews and audits are crucial for this step. Be on the lookout for:

- Multiple systems handling one business process i.e. multiple document management areas, supplier databases, internal training systems;

- Confusion or ambiguity about process steps – ‘calls for help’;

- Duplicated work;

- Excessive numbers of processes;

- Customer feedback (customers are attuned more than anyone to quality issues!);

- Multiple sources of truth;

- Excessive data collection times for reporting;

- Spontaneous workarounds, ‘reinventing the wheel’ when things go wrong.

KPIs are also vital here. More KPIs isn’t necessarily better, though – thinking back to your stakeholder requirements, identify a handful of ‘North Star’ KPIs and encourage departments to stick to them with frequent check-ups.

Process KPIs might include:

- Average process age/time to complete tasks;

- % of processes where assigned resources exceeds planned number;

- Average process overdue time and % of overdue processes;

- Defects and non-conformances.

Service quality KPIs could be:

- Complaint resolution time;

- Number of complaints/escalations;

- NPS;

- Cycle time from customer request to delivery.

And broader quality and compliance KPIs could include:

- Non-conformances found in audits;

- Non-conformance resolution time;

- Cost of poor quality (COPQ);

- Frequency of reviews, audits, or inspections per quarter.

- Improvement

Using these KPIs, continuous improvement should be at the heart of your quality culture and daily activities.

In the same way that relevant personnel should be involved in how processes are built and followed, they should also be consulted when considering opportunities for improvement and refinement.

‘As-Is’ thinking should be ingrained through careful training and communication, with processes which run across departments interrogated in the same way by those different departments.

A robust quality culture should encourage your employees to consider:

- ‘As Is’: How are current processes executed? Where are the areas of weakness/variation? What is working well, and why?

- ‘To Be’: How can processes be improved? How can steps, systems, and tasks be minimized and simplified?

- ‘To Do’: Who needs to be involved in the change? How should people be trained on the change? When does the change need to be actioned by?

The role of leadership in a culture of quality

The right environment must be created for a quality culture to flourish. And while every business is different, some typical components of a culture of quality are common and only consistent top-down leadership from the C-suite can get them in place.

Where ‘management’ concerns itself with tangible, measurable capabilities like processes, ‘leadership’ in this context becomes something less objective and more focused around behavior.

Ultimately, a quality culture is about ensuring all layers of employees understand, and are motivated by, organizational goals and objectives, and how they contribute individually towards them. In a competitive, quality-focused business with a robust quality culture, organizational and quality goals should be one and the same.

Set challenging goals and targets. Couple them with an atmosphere of trust where employees feel comfortable coming forward with improvement suggestions, and empowered with the right training, resources, and autonomy to start actioning them.

Giving generous boundaries, forgiving mistakes, connecting employees to a shared single source of truth, and offering SMART-driven growth plans are all softer behavioral steps conducive to a quality culture.

Quality should be celebrated, too, so consider ways to reward teams and departments for their contributions. Set friendly competitions around quality KPIs and reward employees who suggest an improvement which is implemented.

Business leaders should also:

- Ensure adequate resources for a strong, effective QMS, including digital tools for info-sharing and automation (more on that below);

- Promote risk- and opportunity-based thinking;

- Turn quality policies and objectives from tickbox audit requirements into operational ingredients aligned with the strategic direction of the business;

- Communicate the significance of quality and why everyone should participate;

- Lead by example.

Choosing the right tools for a quality culture

The data streams, tools, processes, and systems your business uses will determine how easy or difficult your quality cultural journey will be.

Legacy quality tools like paper, spreadsheets, and Dropbox folders offer a basic level of communicating and sharing information, but will creak and leak as your business grows. They also demand high levels of admin which can distract from value-adding activities.

Dedicated tools like electronic quality management platforms are growing in popularity as a result of the push for a quality culture. They offer automation of time-heavy compliance and quality management tasks while allowing refocus on quality improvement and culture-building opportunities.

The FDA, for instance, demands that regulated businesses have properly organized and maintained electronic records and signatures in Part 11 of its Title 21 Code of Federal Regulations. Quality-centric organizations are therefore investing in dedicated 21 CFR Part 11 software which offers this capability at a stroke, eliminating the need to plan and maintain this activity and allowing quality cultural work to happen in its place.

Investing in new digital tools, especially cloud-based tools, doesn’t only free up time – it connects remotely distributed colleagues to centralized and harmonized sources of information wherever they are. This, in turn, instills uniformity and eliminates guesswork and ambiguity from day-to-day processes.

Leading software systems can even unlock trend visibility for quality events like defects and complaints, allowing smarter, data-driven corrective action to be taken and continuous improvement to become part and parcel of your daily operation.

For businesses looking to bring a real quality culture to life, it’s worth considering which tools and systems can make the journey simpler.

Conclusion: Make a quality culture your objective

Done properly, a culture of quality is your organization’s secret weapon for beating the competition and lifting the lid on customer-centric growth.

Taking the time now to sow the seeds of a quality culture could be the difference between a good business and a great one!

What do you think is the most important element of a culture of quality? Let us know in the comments below!

Alex Pavlović has worked in the quality and compliance space for 5 years, producing a range of industry content to help Qualio web and blog visitors understand the complex and highly regulated environments of modern life science. He has produced training courses, webinars, whitepapers, blog posts, e-books and more on a range of life science quality topics, from GxP to ISO 13485.

Workflows

Workflows Forms

Forms Data Sets

Data Sets Pages

Pages Process AI

Process AI Automations

Automations Analytics

Analytics Apps

Apps Integrations

Integrations

Property management

Property management

Human resources

Human resources

Customer management

Customer management

Information technology

Information technology

Oliver Peterson

Oliver Peterson is a content writer for Process Street with an interest in systems and processes, attempting to use them as tools for taking apart problems and gaining insight into building robust, lasting solutions.